In the fast-paced retail environment, PDQ Display Boxes (Pretty Darn Quick) are vital for last-mile marketing. Beyond aesthetic appeal, the primary technical consideration for packaging engineers and B2B buyers is structural integrity. The display must resist collapse under the maximum weight of the product and maintain its form when stacked or handled. Achieving optimal stability relies on advanced design in the base and side walls, directly impacting the Load bearing capacity of PDQ base designs.

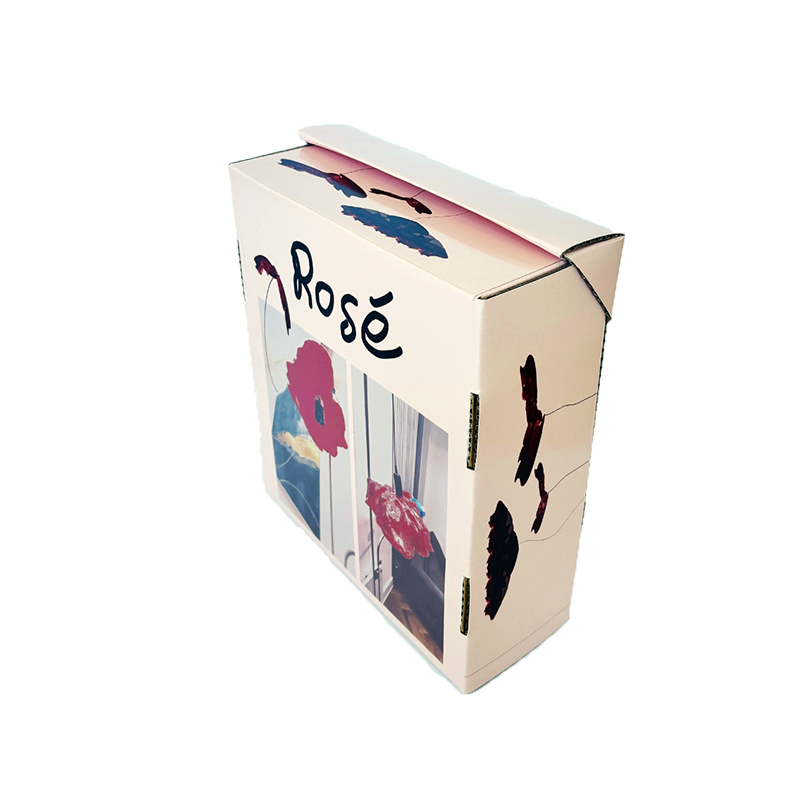

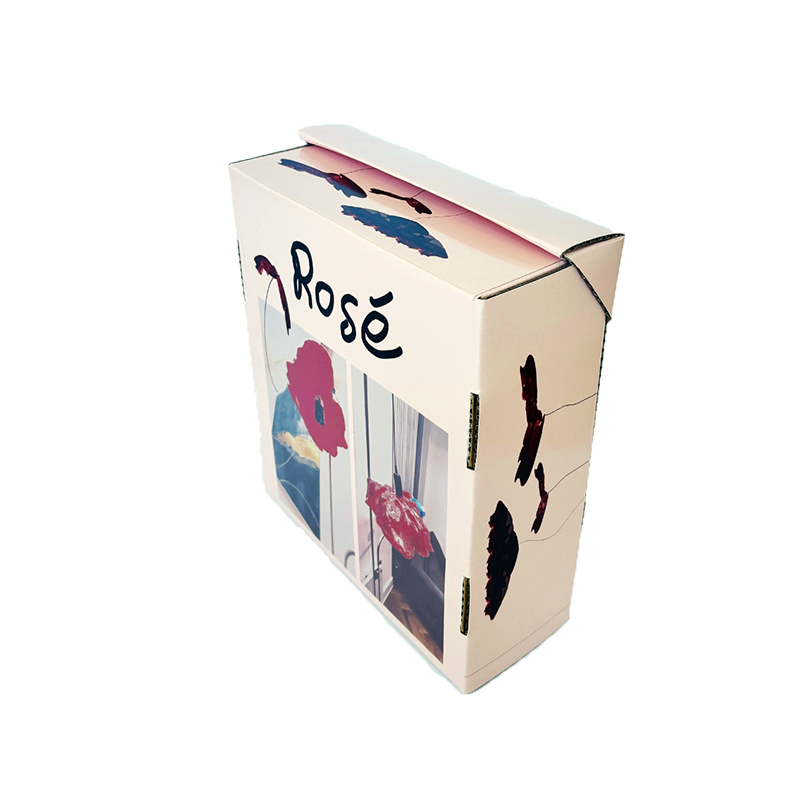

PDQ Quick-Pack Environmentally Friendly Packaging Paper Box, Folding Gift Box

The Foundation of Strength: Load bearing capacity of PDQ base designs

The base structure is the most critical element, as it bears the entire static load and must resist failure due to concentrated point stress from products.

Self-Locking Base vs. Double-Walled Base Structure

- Self-Locking Base: This design (often a snap-lock or crash-lock) prioritizes fast, tool-free assembly, aligning with the "PDQ" promise. Its strength is derived from interlocking tabs, making it suitable for moderate loads.

- Double-Walled Base: This requires an extra layer of material, typically achieved by folding inner flaps or using a double-laminated bottom sheet. This structure significantly increases the contact surface area and material thickness, thereby maximizing the Load bearing capacity of PDQ base designs, essential for heavy goods.

Utilizing the Edge Crush Test (ECT) for Base Material Selection

The Edge Crush Test (ECT) value of the corrugated board dictates the ultimate compression strength. When specifying material for the base, a higher ECT rating ensures better resistance to buckling, especially for displays carrying multiple tiers of product weight.

Base Design Performance Comparison Table

| Base Structure Type |

Assembly Time (Relative) |

Relative Load Capacity |

Material Consumption |

| Self-Locking (Single-Wall) |

Fastest (Aids PDQ goal). |

Moderate (Relies heavily on material grade). |

Lowest. |

| Double-Walled / Laminated |

Slower (Requires more folding). |

Highest (Best for demanding Load bearing capacity of PDQ base designs). |

Highest (Requires more board). |

Reinforcing Verticality: Engineering side wall support for retail boxes

Beyond the base, the vertical Structural stability of corrugated retail displays is governed by the side walls, which must withstand both internal pressure and external forces.

The Role of Flute Direction in Side Wall Compression Strength

- Vertical Flutes: For maximum vertical compression strength, the corrugated flutes should run perpendicular to the base (vertically). This arrangement leverages the corrugated structure's natural columnar strength, critical for Engineering side wall support for retail boxes that need to support multiple layers of product.

- Horizontal Flutes: These offer better bending and wrapping properties, but significantly compromise vertical stacking and compression strength.

Strategic Placement of Internal Tabs and Locking Mechanisms

Internal support tabs, double-thickness side panels, and integrated locking mechanisms are designed to prevent the side walls from bowing outwards under the pressure of the displayed products. This strategic Engineering side wall support for retail boxes ensures the rectangular form factor is maintained throughout its retail life.

Material Science: Corrugated board selection for PDQ strength

The core specification for PDQ Display Boxes rests on selecting the correct corrugated medium, a key part of the Corrugated board selection for PDQ strength process.

Comparing Flute Profiles (E-Flute vs. B-Flute vs. C-Flute)

- E-Flute (Fine): Excellent for graphics and small boxes. Provides a smooth print surface but offers the lowest cushioning and structural strength.

- B-Flute/C-Flute (Standard): Provides a balance of cushioning, strength, and printability. Often laminated onto a high-quality top liner for graphic displays.

Moisture Resilience and Coating Options

Moisture significantly degrades the strength of corrugated board. Corrugated board selection for PDQ strength in high-humidity or refrigerated environments necessitates using water-resistant coatings or wax impregnation, though this must be balanced against sustainability goals.

End-Use Demands: PDQ display box stacking strength requirements

The lifecycle of a display box often includes stacking in back rooms or on pallets, making stacking strength crucial.

Assessing Structural stability of corrugated retail displays during Transportation

- Dynamic Stability: The assembled PDQ Display Boxes must resist shifting and rack during palletized transportation. This requires high frictional coatings on the exterior and rigorous testing to ensure the Structural stability of corrugated retail displays is not compromised before it reaches the shelf.

Calculating Stacking Load (Box Compression Test)

The Box Compression Test (BCT) determines the maximum load a box can safely withstand when stacked. This test is the final validation that the overall design, from the base to the side wall engineering, meets the rigorous PDQ display box stacking strength requirements for safe and efficient warehousing.

Suzhou New Century Color Printing Co., Ltd.: Driving Packaging Quality and Service

Suzhou New Century Color Printing Co., Ltd., established in 2000, is a large, high-tech enterprise specializing in paper color printing and corrugated boxes, serving as a governing unit of the Jiangsu Printing Industry Association. Located in Suzhou with highly convenient transportation, our company utilizes advanced printing equipment and strong technical force to provide superior packaging solutions. We emphasize comprehensive quality management, being certified under ISO9000, ISO14000, and GMI. Our expertise lies in ensuring the highest PDQ display box stacking strength requirements and optimal Load bearing capacity of PDQ base designs through precise material science and structural engineering. We adhere to the business philosophy of "keep improving product quality and serve customers with honesty and trustworthiness," focusing on full process control and continuous improvement to ensure that every order of PDQ Display Boxes meets your exact technical specifications for structural integrity and print quality.

Frequently Asked Questions (FAQ)

1. What is the key design consideration for maximizing the Load bearing capacity of PDQ base designs?

The key consideration is increasing the material thickness and contact area, typically achieved by utilizing a double-walled or double-laminated base structure rather than a simple single-layer self-locking base.

2. How does the flute direction affect Structural stability of corrugated retail displays?

For maximum vertical stacking strength, the corrugated flutes must run vertically (perpendicular to the base). This allows the flutes to act as vertical columns, providing the highest possible compression strength (BCT value).

3. What is the main trade-off when selecting materials in the Corrugated board selection for PDQ strength process?

The main trade-off is between strength and print quality. Thicker, stronger flutes (like C-Flute) offer high load bearing but result in a rougher surface, while E-Flute offers a smooth surface for high-resolution graphics but lower strength.

4. What specific engineering technique is used for Engineering side wall support for retail boxes to prevent bowing?

Techniques include incorporating internal locking tabs, designing the side walls with double material thickness, or strategically folding the top tray lip down to the box interior to stiffen the upper edges.

5. What is the role of the Box Compression Test (BCT) in relation to PDQ display box stacking strength requirements?

The BCT determines the actual maximum load a box can withstand before failure. This value is used to calculate safe stacking heights for the PDQ Display Boxes in the warehouse and transit stages, ensuring they meet the required durability standards.

Français

Français Español

Español عربى

عربى