I. The Critical Role of Corrugated Structure in Retail Success

PDQ Display Boxes (Product Dispensing Quick) are an essential component of modern retail merchandising, serving as silent salespeople at the point of purchase. Their primary function is two-fold: to drive impulse buys through high-impact graphics and to safely and reliably present products to the consumer. For B2B procurement and wholesale buyers, the critical challenge lies in precisely balancing structural integrity, print quality, cost-effectiveness, and increasing sustainability mandates. A slight miscalculation in material specification can lead to display failure, product damage, or unnecessary expenditure. As a governing unit of the Jiangsu Printing Industry Association, Suzhou New Century Color Printing Co., Ltd. has specialized since February 2000 in delivering this balance through advanced paper color printing and corrugated box manufacturing. Our adherence to stringent standards, including ISO9000 and GMI certification, ensures that every PDQ Display Boxes project starts with the right technical foundation. Our commitment is rooted in the quality policy of "full participation and full process control; keeping promises and continuous improvement," guaranteeing solutions that meet the highest standards of performance and social responsibility.

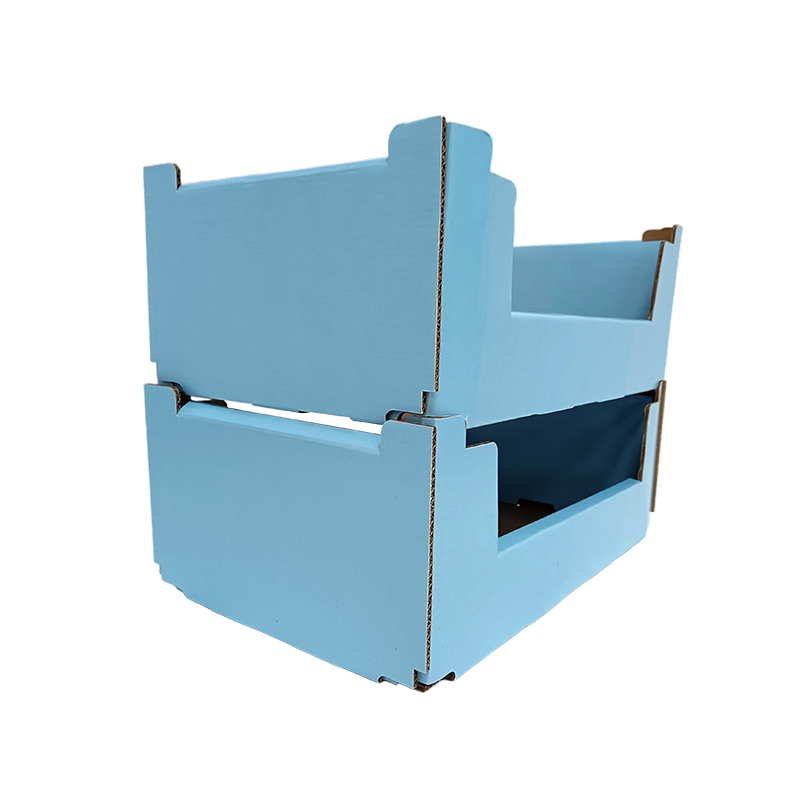

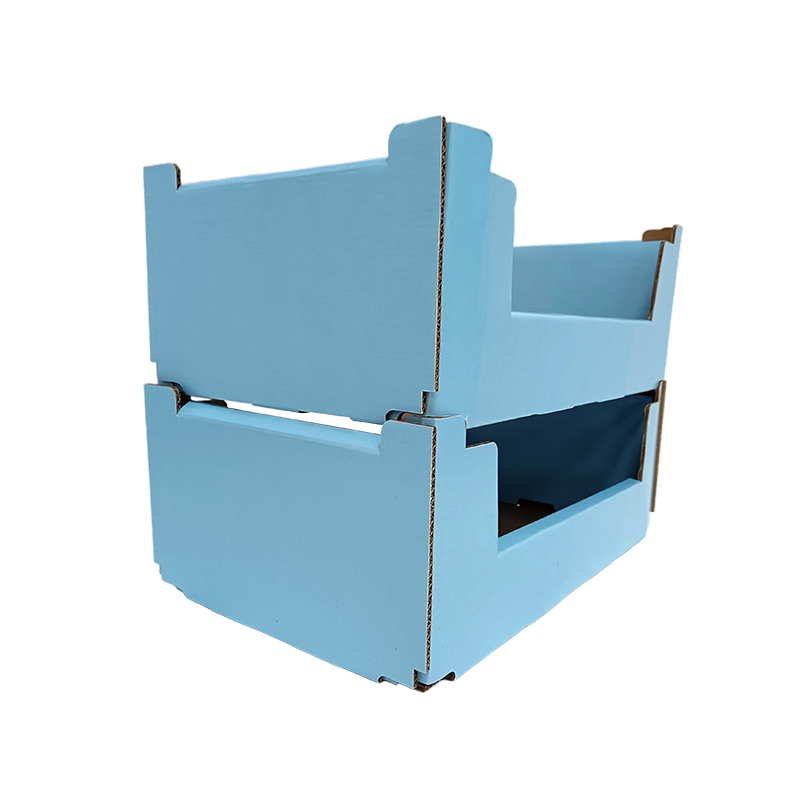

Tear-Off Foldable PDQ Tote Cartons

II. The Technical Selection of Corrugated Flute Grades for PDQ Displays

The strength and print quality of any corrugated packaging—including PDQ Display Boxes—is fundamentally determined by its flute structure. The flute, the wavy layer sandwiched between the linerboards, dictates the overall caliper, crush resistance, and stacking strength. For retail displays, the focus often narrows to finer flutes, which offer a superior surface for litho-laminated graphics. We must determine the optimal flute grade for counter display strength based on the product's weight and the display's lifespan. The most common single-wall options considered for displays are E-flute and B-flute, sometimes in combination for heavier applications. Here is a comparison of their characteristics:

Comparison of Common Single-Wall Flutes for Displays

E-flute is generally preferred for its excellent print surface and reduced board thickness, making it ideal for compact designs. B-flute, however, offers superior cushioning and rigidity, often chosen for displays holding heavier or more delicate items. The technical decision must weigh the graphic demands against the required Box Compression Test (BCT) values.

| Flute Grade |

Flutes per Linear Foot (Approx.) |

Flute Height (Inches) |

Primary Benefit for PDQ |

Recommended Use Case |

| E-Flute |

90-96 |

1/16 |

Excellent Printability, Smooth Surface |

Small, high-graphic counter displays for light products (e.g., cosmetics, snacks). |

| B-Flute |

47-50 |

1/8 |

Superior Cushioning, High Rigidity |

Displays for medium-weight products (e.g., small electronics, bottled items). |

A. E-Flute: The Standard for High-Graphic PDQ Displays

E-flute is the industry standard for high-end point-of-purchase (POP) and PDQ Display Boxes. Its approximately 90-96 flutes per linear foot create a very stable, smooth surface. This high flute density minimizes the "washboard" effect—the visibility of the corrugated lines—on the final printed sheet, which is crucial for achieving high-fidelity lithography. E-flute provides sufficient compression strength for most counter display applications where product weights are modest. The reduced caliper (thickness) also results in less material volume, lowering shipping costs and requiring less space in the retail environment.

B. B-Flute: Maximizing Stability and Protection

B-flute is a robust alternative, featuring fewer flutes but a greater height (approximately 1/8 inch). While its slightly coarser surface texture may be noticeable under high-graphic printing compared to E-flute, it provides significantly better crush resistance and cushioning. When designing PDQ Display Boxes for products that are prone to vertical compression damage or have a higher unit weight, B-flute should be specified. It is often the choice for displays that need enhanced resistance to transit handling or for longer-term placement in-store, ensuring greater corrugated flutes for PDQ display stability.

C. Double-Wall Combinations: The Ultimate in Structural Integrity

For large floor-standing displays or counter displays holding exceptionally heavy merchandise (e.g., multiple units of liquid detergent or tools), single-wall boards may not meet the BCT requirements. In these cases, a double-wall combination, such as EB-flute (E-flute laminated onto a B-flute layer), provides maximum rigidity. The E-flute faces outward for print quality, while the B-flute provides the robust cushioning and stacking strength. The decision to use double-wall structure must be carefully weighed against the higher material cost, ensuring the enhanced durability justifies the expenditure.

III. Cost vs. Strength: Engineering the Perfect PDQ Balance

A key function for the B2B buyer is to source cost-effective materials for temporary retail displays without risking structural failure, which could damage the brand's reputation and lead to costly claims. The material selection—flute grade, linerboard basis weights, and recycled content—is the primary lever for cost control. The technical specification of the linerboard (e.g., 200# Test vs. 275# Test) directly impacts both cost and strength. Our engineers utilize advanced structural design software to perform virtual BCT analysis, allowing us to identify the most efficient material combination. Often, cost savings are achieved not by downgrading the flute, but by optimizing the die-cut pattern and structural geometry (e.g., adding internal reinforcement tabs or utilizing better locking mechanisms). This ensures that while we achieve excellent corrugated flutes for PDQ display stability, we are not over-engineering the solution.

| Cost/Strength Factor |

Impact on Strength (BCT) |

Impact on Cost |

Notes for Optimization |

| Higher Flute Density (e.g., E vs. C) |

Lower stacking strength, but better crush resistance |

Generally lower material volume/cost |

Best for high-graphic, lighter loads. |

| Higher Linerboard Basis Weight |

Significantly increases BCT and Edge Crush Test (ECT) |

Increases material cost per unit |

Necessary for heavy loads; cost justified by preventing failure. |

| Double-Wall Flute (e.g., EB) |

Highest BCT/Stacking Strength |

Highest material cost |

Only specify for mission-critical, heavy-load displays. |

IV. Adhering to Brand Sustainability: FSC and High Recyclability

Modern B2B purchasing mandates increasingly prioritize sustainable sourcing. This requires manufacturers of PDQ Display Boxes to provide verifiable documentation regarding fiber origin and material composition. As a company that has passed the ISO14000 environmental management system certification, Suzhou New Century Color Printing Co., Ltd. is uniquely positioned to meet these demands with expertise and certified processes. We specialize in sourcing and producing displays using FSC-certified corrugated for retail displays. The Forest Stewardship Council (FSC) Chain-of-Custody (CoC) certification is the international gold standard, ensuring that the paperboard fiber originates from responsibly managed forests. For our partners, specifying FSC-certified stock provides irrefutable proof of their commitment to environmental stewardship. Furthermore, we offer a full range of eco-friendly PDQ box material options, which are 100% recyclable in standard paper recycling streams. We guide clients on the trade-offs between Virgin and Post-Consumer Recycled (PCR) content. While PCR content is highly desirable for sustainability metrics, it can sometimes marginally reduce fiber strength, which must be compensated for by adjusting flute size or basis weight to maintain the required BCT value. Our established GMI and quality systems ensure that sustainability does not come at the expense of structural integrity, aligning with our philosophy of "maintaining sustainable development while not forgetting various management tasks surrounding product quality and social responsibility."

V. Conclusion: Partnership for Excellence in Retail Packaging

The optimal design and manufacturing of PDQ Display Boxes require a highly technical approach, carefully balancing the need for optimal flute grade for counter display strength, graphical excellence, and cost control, all within a framework of verifiable sustainability. For buyers, the choice of a manufacturing partner is critical. Located strategically near major ports and transport hubs—including Shanghai Port and Shanghai Hongqiao International Airport—Suzhou New Century Color Printing Co., Ltd. is positioned to offer highly efficient supply chain solutions. Our high-starting point, advanced equipment, and strong technical force, combined with a commitment to FSC-certified corrugated for retail displays and eco-friendly PDQ box material options, allow us to offer unparalleled service. We welcome the opportunity to establish a long-term supporting cooperative relationship based on integrity, pragmatism, and common development, providing tailored, engineered solutions for your next retail campaign.

VI. Frequently Asked Questions (FAQs)

Q1: What is the primary difference between E-flute and B-flute for PDQ Display Boxes?

- A: E-flute is thinner and has a higher density of flutes, providing a smoother surface ideal for high-resolution graphics, making it suitable for light products. B-flute is thicker and more rigid, offering better cushioning and structural strength for heavier items or more rigorous handling, ensuring greater corrugated flutes for PDQ display stability.

Q2: How does a manufacturer verify that the corrugated board is FSC-certified?

- A: Verification is achieved through a Chain-of-Custody (CoC) certification, such as the one maintained by Suzhou New Century Color Printing Co., Ltd. This ensures that the fiber can be traced from an FSC-managed forest through all stages of processing and manufacturing. The final product can then carry the official FSC label.

Q3: How can we achieve cost savings for our temporary retail displays without compromising strength?

- A: Achieving a balance involves smart engineering. Rather than simply using cheaper, less durable board, we focus on structural optimization—improving the design geometry, load distribution, and utilizing the most cost-effective materials for temporary retail displays that meet the minimum required BCT score. Efficiencies in print runs and logistics also play a significant role.

Q4: Is it possible to use 100% Post-Consumer Recycled (PCR) content in PDQ Display Boxes?

- A: Yes, it is possible. Many eco-friendly PDQ box material options utilize high or 100% PCR content. However, PCR fiber is typically shorter and slightly weaker than virgin fiber. Our engineers may recommend slightly higher basis weights or a different flute profile to compensate and ensure the display maintains its required load-bearing capacity.

Q5: When should a double-wall (e.g., EB-flute) structure be considered for a counter PDQ display?

- A: Double-wall structures should be considered when the total product load exceeds the reliable stacking strength of single-wall boards, or when the display is exceptionally large and needs to withstand external forces over a long period. The higher cost is justified when optimal flute grade for counter display strength is critical for safety and longevity.

Français

Français Español

Español عربى

عربى